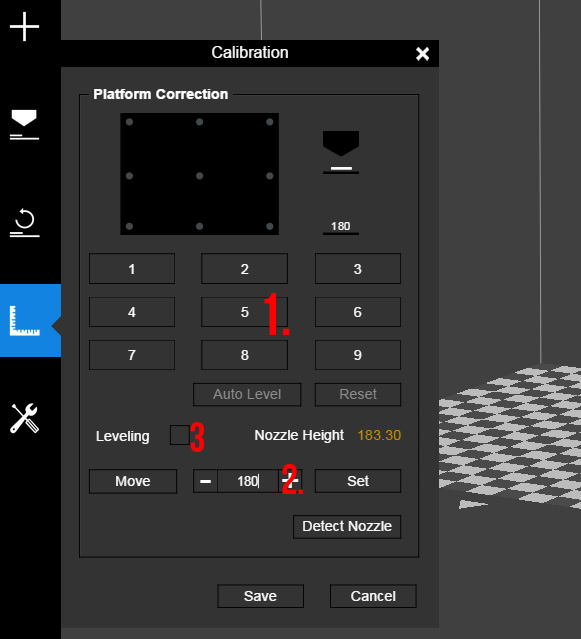

Some printers are capped at 250 ☌, particularly those that use PTFE tubing as the idler inside the extruder assembly. The first thing you’ll have to as is if your printer is capable of reaching these temperatures. Although PETG practically eliminates any issues with warping, you’re still bound to run into the other complications associated with high-filament printing. A range of 220 to 265 ☌ is commonly used, but the recommendations of your specific filament brand may vary slightly. The main reason why PETG gets compared with ABS so much is the fact that it prints at relatively high temperatures. Printing temperature, speed, and retraction You can set this as both the initial nozzle height and the height for the rest of the print. If you want to do an accurate nozzle height calibration, then a setting of 0.02 to 0.05 mm from the nozzle to the print bed would be a good starting point. We prefer going as high as possible for aesthetics, so start at the highest setting and work your way down incrementally if you run into any problems with bed adhesion. If you already have a tried and tested nozzle height setting for ABS or PLA, then you can comfortably set a value that’s two or three times higher with PETG. This is a technique done to “squish” the first layer against the bed and help with base layer adhesion. Since PETG has no bed adhesion problems, there’s no need to set the nozzle too low for the base layer. Don’t use any BuildTak as you’ll just end up with a ruined BuildTak surface every time you work on a PETG project (which can get pretty expensive). Do not print directly on glass, lest you end up with scratches on the surface of your print bed. To make sure that the print comes off easily enough, we recommend using an adhesion aid that will come off along with the print, such as glue stick or hairspray. If you’re still having bed adhesion problems at these settings, you can as high as 100 ☌. We recommend a setting of 70 to 80 ☌ for the heated bed. The drastic temperature drop will almost certainly lead to a warping problem if your print bed is too cold. If you don’t take the necessary precautions, you could up with a finished print that you can’t get of the print bed without causing any damage.īecause of the high printing temperature of PETG, you still can’t do without a heated printing bed.

PETG is also somewhat problematic, but in the opposite manner – it sticks a little too well. If you’ve ever printed with ABS, then you know how complicated it is to get the first layer of the ABS print to stick to the print bed.

It can also be printed almost completely clear, making it a great material for ornamental items. It’s a good choice of material for functional parts that need to withstand constant movement or pressure. In summary, PETG gives you almost all the mechanical and chemical advantages of ABS with the same ease of workability as PLA. It also doesn’t release harmful gases while printing, which is one of the worst things about printing with ABS. However, it doesn’t have a large shrinkage factor and has better layer-to-layer adhesion, which means that it doesn’t have serious warping issues. It prints at high temperatures like ABS, thus giving it good heat stability. In the world of 3D printing, PETG has often been touted as representing the best of both worlds of the top two most popular filaments, PLA and ABS. It has excellent chemical resistance and is a good moisture barrier. It also has better optical properties and is easier to work with compared to PET. The “G” in PETG stands for “glycol-enhanced.” The addition of a glycol group makes PETG a little more durable and less brittle. PETG is a derivative of the super-popular polyethylene terephthalate (PET). What are the best printer settings with PETG? What issues with PETG should you be anticipating? What is PETG?

Calibrate cetus3d how to#

In this article, we teach you how to get good prints with PETG, a filament which seems to be on track to becoming one of the most popular today. The downside of having all these filament choices is that each one requires you to learn how to use them. There are filaments that are flexible, those that mimic the finish of wood, and some even have some degree of electrical conductivity. One of the best things about FDM printing is the sheer variety of filaments that you can work with. 3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

0 kommentar(er)

0 kommentar(er)